System-Wide Distribution Improvement

PROJECT SCOPE

A mid-sized utility serving densely populated regions of New England was experiencing low voltage and reliability problems on a number of 4.8kV circuits. The solution was to resupply the area with new 13.8 kV circuits from a new substation.

The client’s design staff was already overtaxed with work, and required assistance to accomplish this without a lengthy delay. The client decided to hire Wagner Technical to accomplish the goal within an acceptable timeframe.

What the Client provided to Wagner Technical:

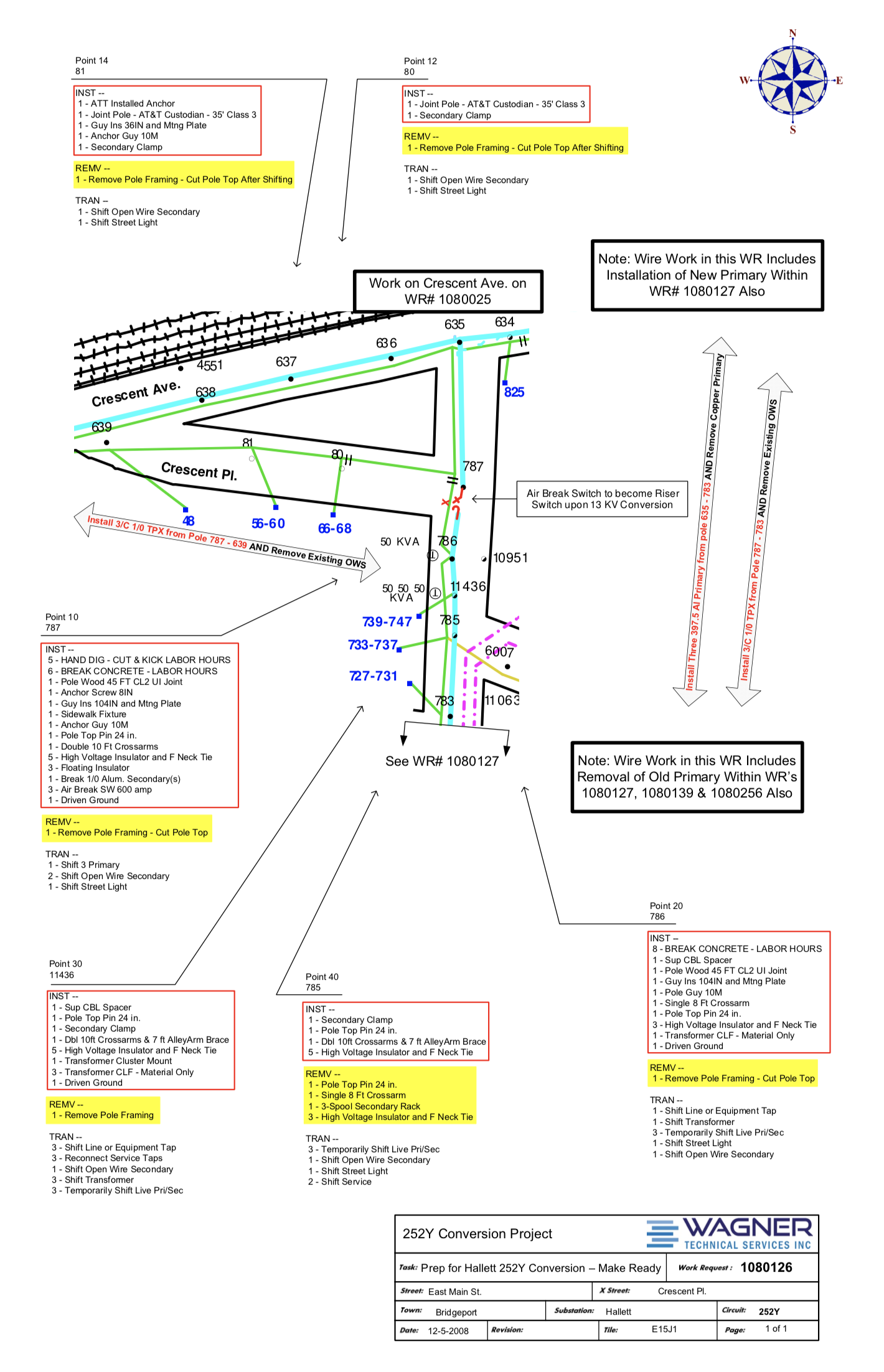

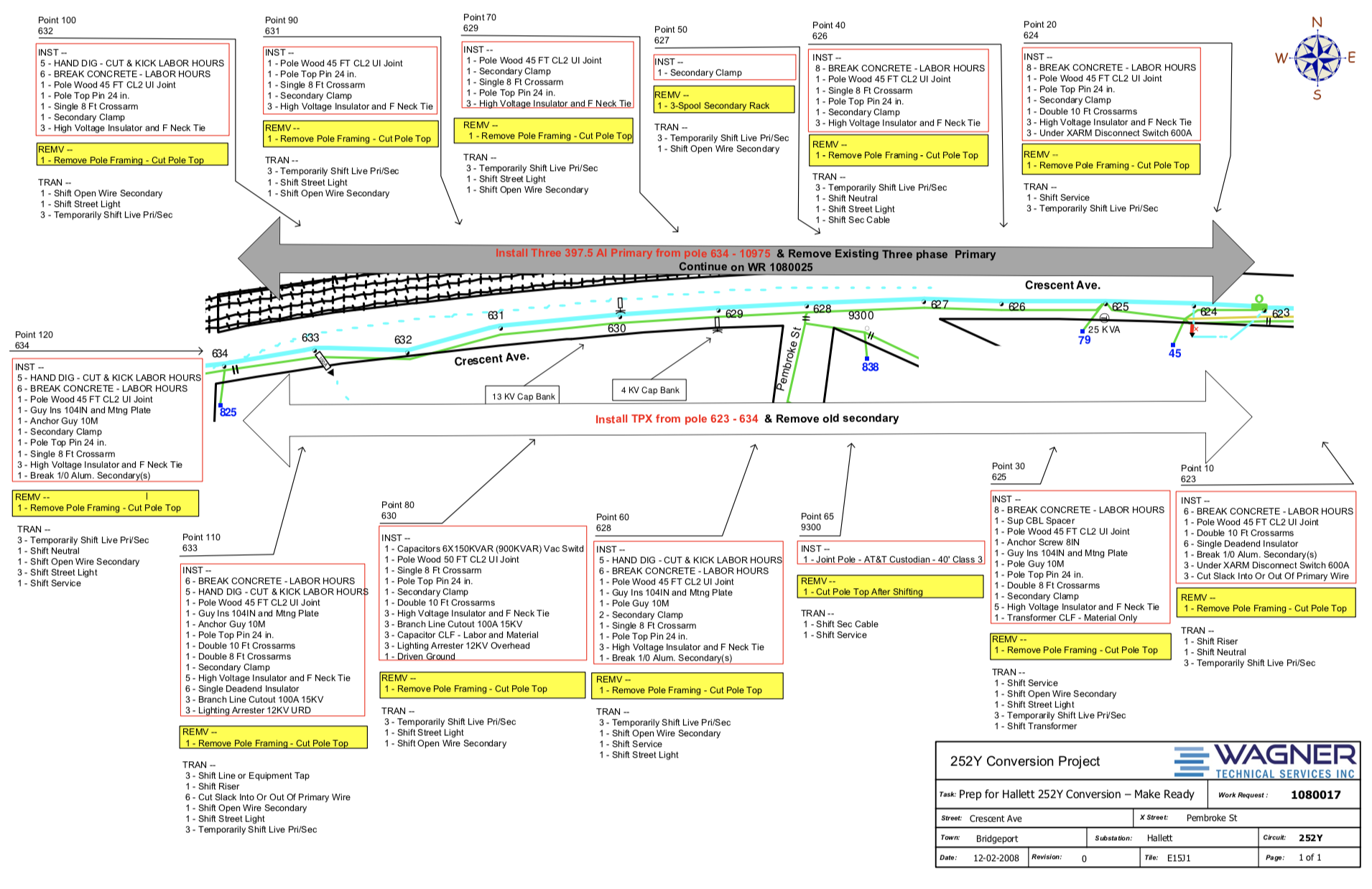

Wagner Technical was given a 2 page scope document, and a one-line diagram showing the desired new circuit configuration. From this they developed a plan to design the new circuits.

Wagner Tech Approach:

To expedite the project Wagner Technical immediately dispatched field technicians to survey the area, noting and photographing existing pole plant and taking measurements to be used later when the design was developed. At the same time, a technician was assigned to take the client’s standards and enter them into Wagner Technical’s proprietary Work Management System (WWMS). This enabled work orders, bills of material, etc. to be produced later as needed.

CHALLENGES

The urban environment of this project presented several challenges:

Challenge: NESC clearance violations that couldn’t be corrected by simply installing taller poles.

Solution: Resupply areas from alternative routes, all developed by Wagner Technical.

Challenge: Inconsistencies in the client’s existing GIS data.

Solution: Wagner Technical communicated directly with the utility’s assigned GIS editor, to correct inconsistencies as they were discovered.

Challenge: The one-line given had no loading information, and very few switch locations.

Solution: Wagner Technical was given access to the client’s load data, and was able to determine appropriate fusing and transformer sizing and placement. Additionally, Wagner Technical determined appropriate field locations for other protective devices such as reclosers and switches.

Deliverables to Client:

Wagner Technical produced standards compliant work order packages which included drawings, and uploaded these into the client’s work management system. Wagner Technical also supplied detailed Bill of Material information to expedite material ordering.

Additionally, project management was simplified when Wagner Technical provided detailed overview maps which enabled the client to easily present the project to both in house personnel and the contractor who was brought on to do the construction.

RESULT

The project was completed as scheduled, without the need to reassign the client’s design staff.